What is Shock Pulse Monitoring and Vibration Analysis?

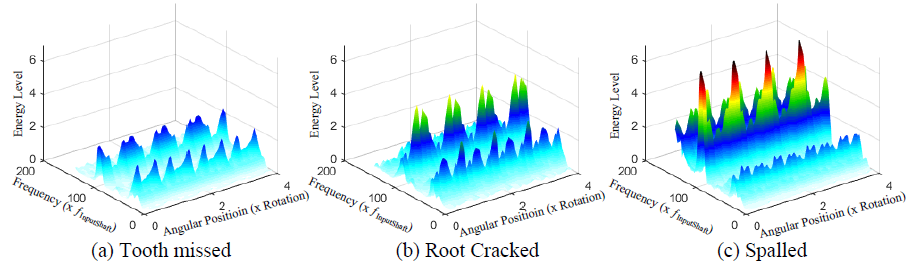

Shock pulse monitoring and vibration analysis is done to analyze the reliability and health of the machines and their components by looking for anomalies and monitoring change from the vibration signature of a system. The vibration of any object in motion is characterized by variations of amplitude, intensity, and frequency. These vibration signatures can be correlated to physical phenomena, making it possible to use vibration data to gain insights into the health of equipment.

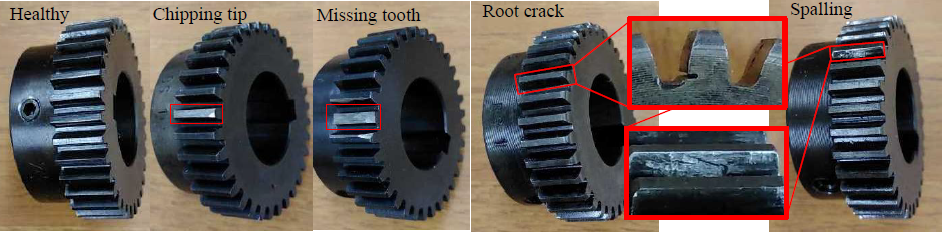

Vibration Analysis on a Gearbox with Different Faulty Conditions

What Should be Inspected?

Benefits of Shock Pulse Monitoring and Vibration Analysis Services

✔ Determine structural or rotating looseness or the presence of resonance

✔ Check bearing concentricity

✔ Detect misalignment or imbalance

✔ Establish your Repair Priorities based on the results

✔ Improve Your Preventive Maintenance Quality and Results

✔ Test Under Load without any planned shutdown