What is Ultrasonic Testing?

With the ever growing world of technology, even sound can be visualized. Air leak detection, and locating discharge from high-voltage systems are some of the applications of acoustic Imaging. The human ear can sometimes hear an air leak in a quiet environment, but in a typical industrial environment, it’s impossible to hear even bigger leaks due to loud background noise. Hence, the importance of ULTRASONIC TESTING.

Elite Thermography uses advanced and quality ultrasonic devices to ensure the accuracy and reliability of our ultrasonic testing.

What is Ultrasound?

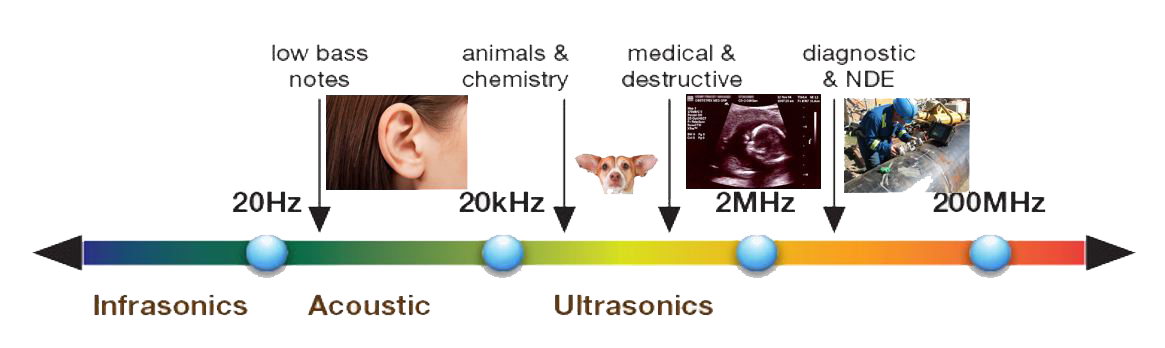

The term “ultrasonic” applied to sound refers to anything above the frequencies of audible sound, and nominally includes anything over 20,000 Hz.

Diagnostic Ultrasound imaging or sonography has been very popular in medicine because it allows an inside view of soft tissues and body cavities without the use of invasive techniques. Sonograms can provide valuable information for diagnosing and treating a variety of diseases and conditions.

Ultrasound is also one of the best Non-destructive Testing used for composite materials, air leaks, partial discharge, bearing and lubrication, and so on.

What Can be Inspected?

✔ Composite materials

✔ Partial Discharge

✔ Corona

✔ Rotating Equipment

✔ Belts

✔ Bearings

✔ Conveyors

✔ Compressed Air

✔ Steam Systems

✔ Natural Gas

Benefits of Ultrasonic Testing :

✔ Non-contact and non-Destructive testing

✔ Detects even the smallest leaks of compressed gases to prevent losses

✔ No downtime required

✔ Avoids catastrophic failure by detecting cause of the problem before failure

✔ Establish your Repair Priorities based on report classification

✔ Improve Your Preventive Maintenance Quality and Results

✔ Test Under Load without any planned shutdown