What is Partial Discharge?

Partial Discharge or PD is one of the first signs of a deteriorating insulation system and can lead to costly repairs or even the failure of medium and high voltage equipment. PD activity is common within medium and high voltage apparatus and is therefore important to detect and measure the severity of the present PD signals. Preventative maintenance routines involving PD measurements can lead to early detection of deteriorating insulation quality and the assessment of manufactured, installed, or repaired asset quality.

It is an important factor in securing any piece of electrical equipment at a minimum voltage as any appliance ages over time and if left undetected can lead to breakdown of the installation system. Elite Thermography conducts this inspection to provide advance warning of a pending insulation failure.

Types of Partial Discharge

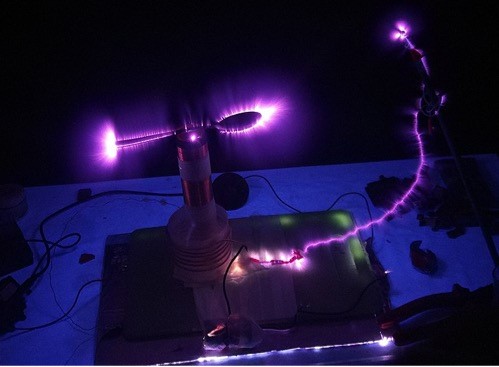

Corona

Corona is the partial discharge that happens in gaseous dielectrics in the presence of inhomogeneous fields. Corona refers to the luminous and visible partial discharges.

Surface

Surface PDs occur at the boundary of different insulation materials. When surface PD is present, it will produce the crackling and ozone smell.

Internal

Internal Partial Discharge happens in voids or cavities within solid or liquid dielectrics. These are silent defect where there will be no sound, smell or visual indication of a problem prior to failure

What Should Be Inspected?

✔ Motors

✔ Generators

✔ Switch gear systems

✔ Transformers

✔ Bus ducts

✔ Splices

✔ Terminations of cables

✔ Bearing

✔ Lubrication

✔ Compressed Air

✔ High Voltage Cabinet

✔ Low Voltage Cabinet

✔ Power Line

Benefits of Partial Discharge Inspection:

✔ Enhance electrical reliability

✔ Identify voids, cracks or other flaws where electrical stresses exceed the insulation capacity.

✔ Predict the electrical equipment which needs to be replaced or repaired

✔ Prevent insulation and equipment failure at an accessible cost

✔ Test Under Load without any planned shutdown