Manufacturing companies improve their line processes to reach higher efficiency or production rate. One of the usual causes of downtime are broken or worn mechanical parts cause the machine to stop working. The company’s loss is great when shutdown happens due to maintenance or repair of production machines.

These downtimes can be reduced with continuous condition monitoring of mechanical parts like gears, bearings, pumps, conveyor belts, and so on.

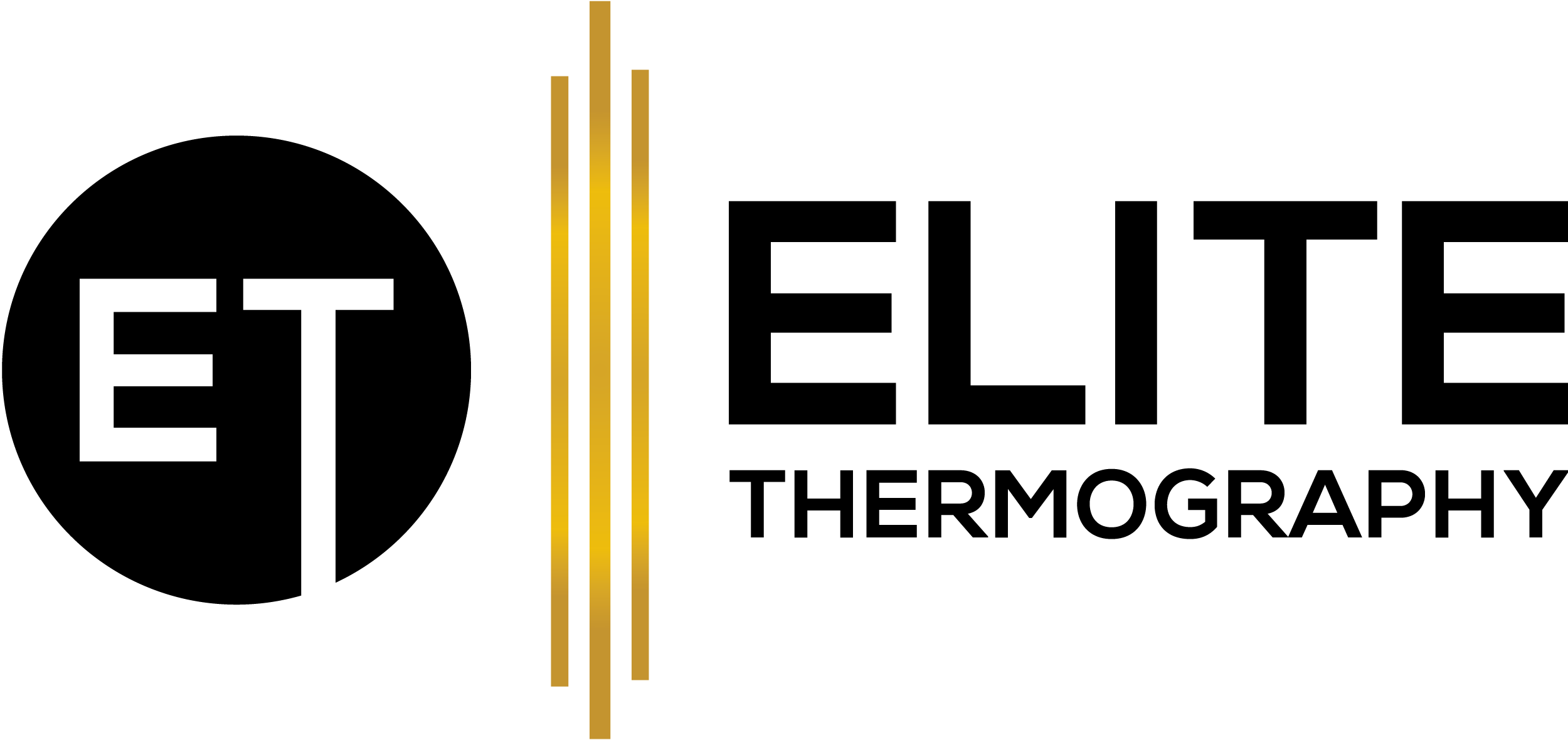

Thermal imaging in Manufacturing

An infrared thermal imaging camera can capture the heat signature of the area or object being monitored and give alarm to the maintenance team if a certain threshold is reached.

This method makes the preventive maintenance planning easier since the relevant personnel can see the actual condition of the mechanical part and foresee when it is bound for repair or replacement. The urgency can also be judged based on the thermal images.

For example, the conveyor belt is heating up abnormally which could mean that the belt is having too much friction. The maintenance team can put proper lubrication as initial action to prevent the machine from completely failing or cause danger to operators.

Why Hikvision camera?

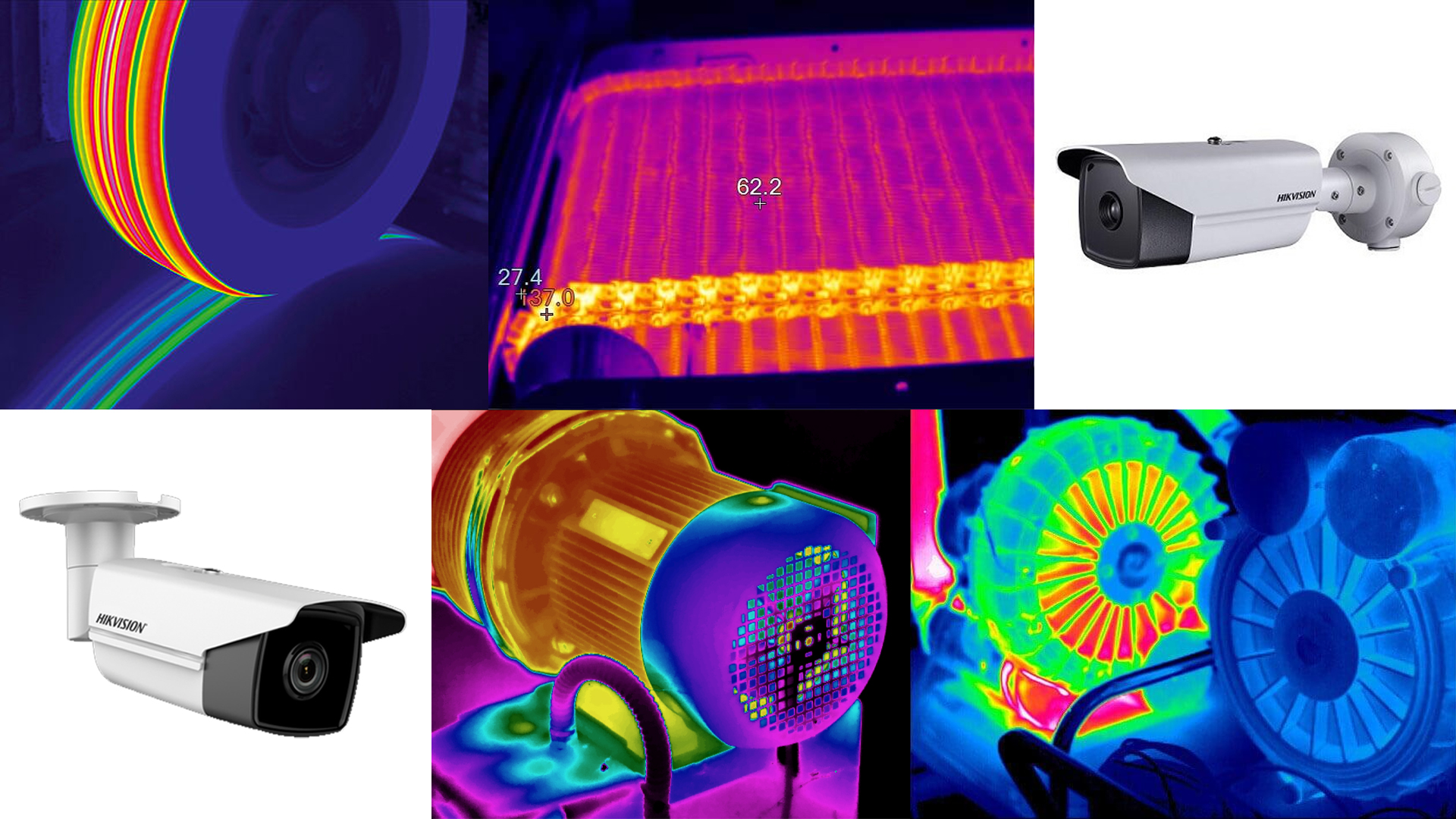

The HIKVISION Thermal Network Bullet camera line consists of models suitable for continuous condition monitoring. The improved temperature exception alarm function guarantees reliability in notifying the key persons to when a mechanical part needs maintenance.

The bullet cameras have bodies that can accommodate large lenses for wider field of view.

They are also easy to install on walls, ceilings and poles. The field of view can be changed without unmounting the camera provided that the new view is in camera range.

Thermal Network Bullet cameras are designed with robust materials that can withstand harsh environment conditions like rain, fog, haze, heat, and dust.

Learn More

https://www.youtube.com/watch?v=lA28JaK7-rE – HikVision Thermal Network Bullet Camera