What is Mechanical Inspection for Thermography?

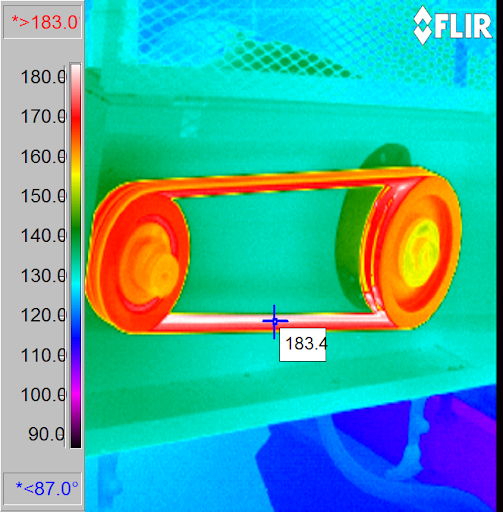

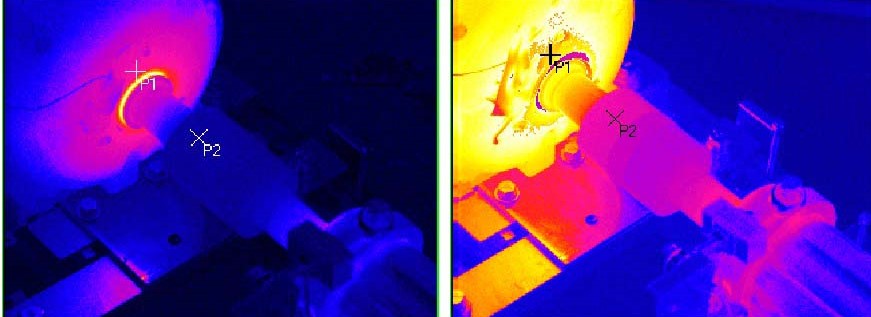

Thermography enables us to conduct mechanical inspections without a full shutdown of the line process or machine. The method is essential in preventive maintenance of electrical motors, conveyor belts, bearings, pumps, steam traps, and more mechanical components. Know the possible problems and the degree of the risk before it even happen.

Maximizing the Potential of Mechanical Inspection

Thermography Advantages :

✔ Non-destructive and non-contact

✔ Reduced downtime

✔ Prevent costly and catastrophic system failure

✔ Plan your repair and maintenance effectively with priorities

✔ Real-time inspections

✔ Fast and Quality assessment reports

ITC CERTIFIED THERMOGRAPHER & ENGINEERS

When it comes to inspecting mechanical equipment with infrared, certain conditions are needed. We have ITC certified Thermographers and Engineers. Proper training is essential to successfully operate these systems.